Key Considerations When Customizing Pultrusion Molds

Custom pultrusion molds play a crucial role in ensuring the quality, precision, and production efficiency of FRP profiles. Whether for fiberglass rebar, square tubes, channels, or flat panels, a well-designed mold directly determines the success of pultrusion production. Below are the key factors that both manufacturers and customers should consider when customizing a pultrusion mold.

1. Collecting Complete Design Data

Before mold design, the manufacturer should obtain the customer's full technical information, including:

- 2D/3D drawings or a physical sample of the product

- Profile dimensions (width, height, thickness, and tolerance)

- Application field (construction, chemical, electrical, etc.)

- Working environment (outdoor, high temperature, corrosion, etc.)

2. Clarifying Material and Resin System

The material system affects the mold design and heating control. Customers should specify:

- Reinforcement type: fiberglass, carbon fiber, or basalt fiber

- Resin type: unsaturated polyester, vinyl ester, epoxy, or phenolic resin

- Surface requirements: smooth, matte, with gel coat, or colored finish

3. Ensuring Equipment Compatibility

To guarantee proper fit and efficiency, the mold must match the customer's pultrusion line. The following details are important:

- Existing equipment model and puller type

- Heating method: electric, oil, or water

- Line speed or production rate

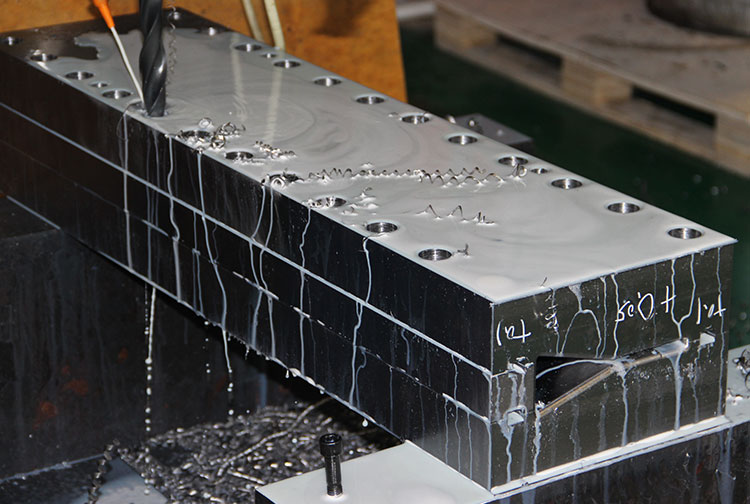

4. Mold Material and Structural Design

High-quality mold steel (such as Cr12, S136, or P20) is commonly used. The structure should include:

- Segmented design for easy cleaning and maintenance

- Multi-zone temperature control for uniform heating

- Polished or chrome-plated inner surface for better release performance

5. Testing, Commissioning, and After-Sales Support

After production, a test run is essential to verify product dimensions and surface quality. Customers should also receive:

- Detailed mold drawings and parameter sheets

- Installation and heating instructions

- Maintenance and cleaning recommendations

- Technical support and remote guidance

6. Customer Confirmation Form (Recommended)

To ensure all specifications are clear before production, Henan Zhongsheng FRP provides a mold confirmation form including:

| Item | Customer Information |

|---|---|

| Profile Name | |

| Dimensions | |

| Material System | |

| Resin Type | |

| Production Speed | |

| Surface Requirement | |

| Equipment Model | |

| Heating Method | |

| Special Requirement |

Conclusion

Customizing a pultrusion mold is not only about machining steel, but also about engineering precision and process understanding. With clear communication between customer and manufacturer, the final mold can achieve excellent performance, long lifespan, and stable production results.

About Henan Zhongsheng FRP

Henan Zhongsheng FRP Co., Ltd. specializes in FRP pultrusion molds, pultrusion machines, and custom fiberglass profiles. We provide one-stop solutions from design to production and after-sales technical support.

Contact us today to get your customized pultrusion mold solution:

www.frpzs.com

Email: Jessica@frpzs.com

WhatsApp: +86 15303735673

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data